Alcohol Based Hand Sanitizer Production Line

Complete turnkey solution for manufacturing high-quality alcohol-based hand sanitizers with advanced automation and quality control

Hand Sanitizer Production Technology

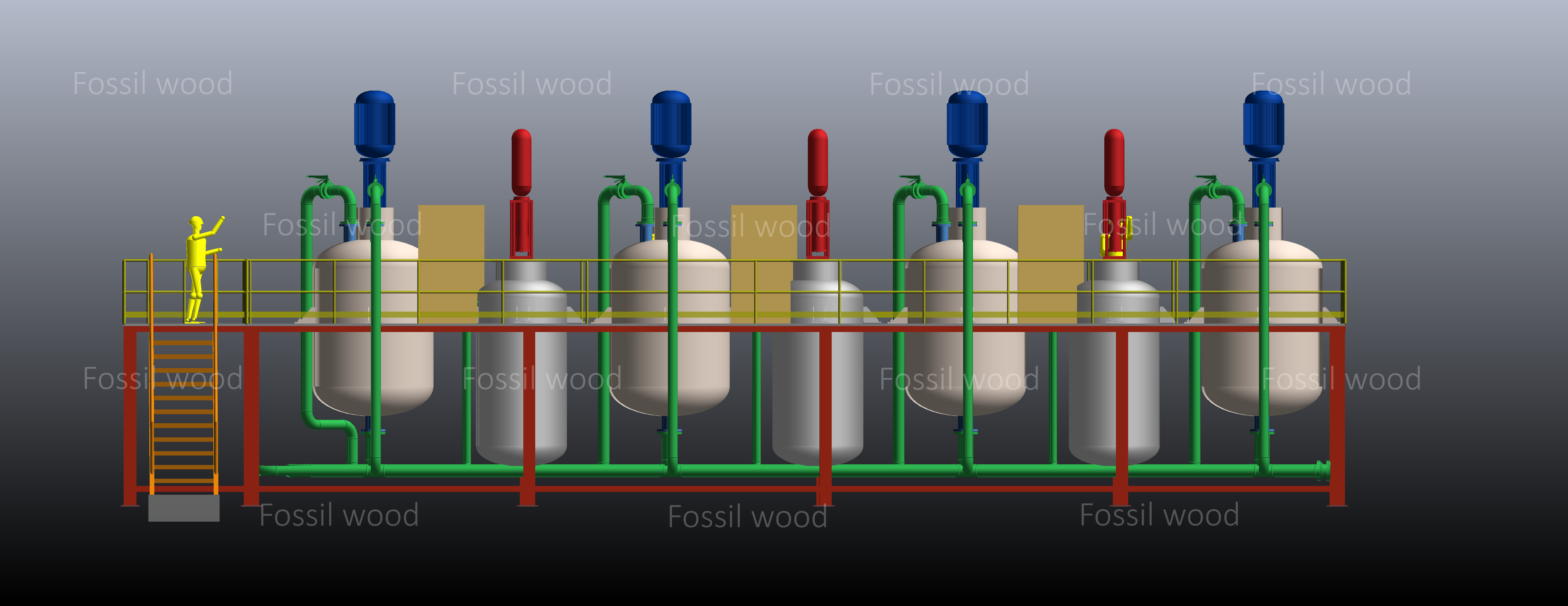

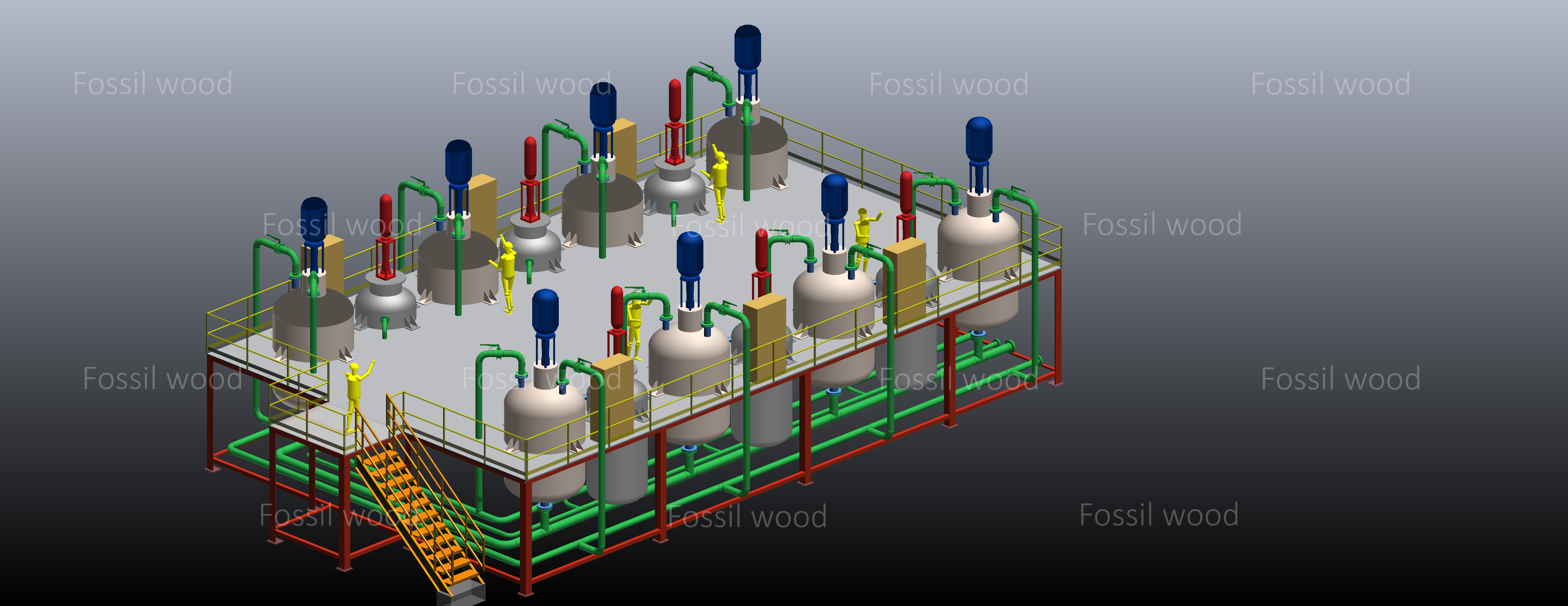

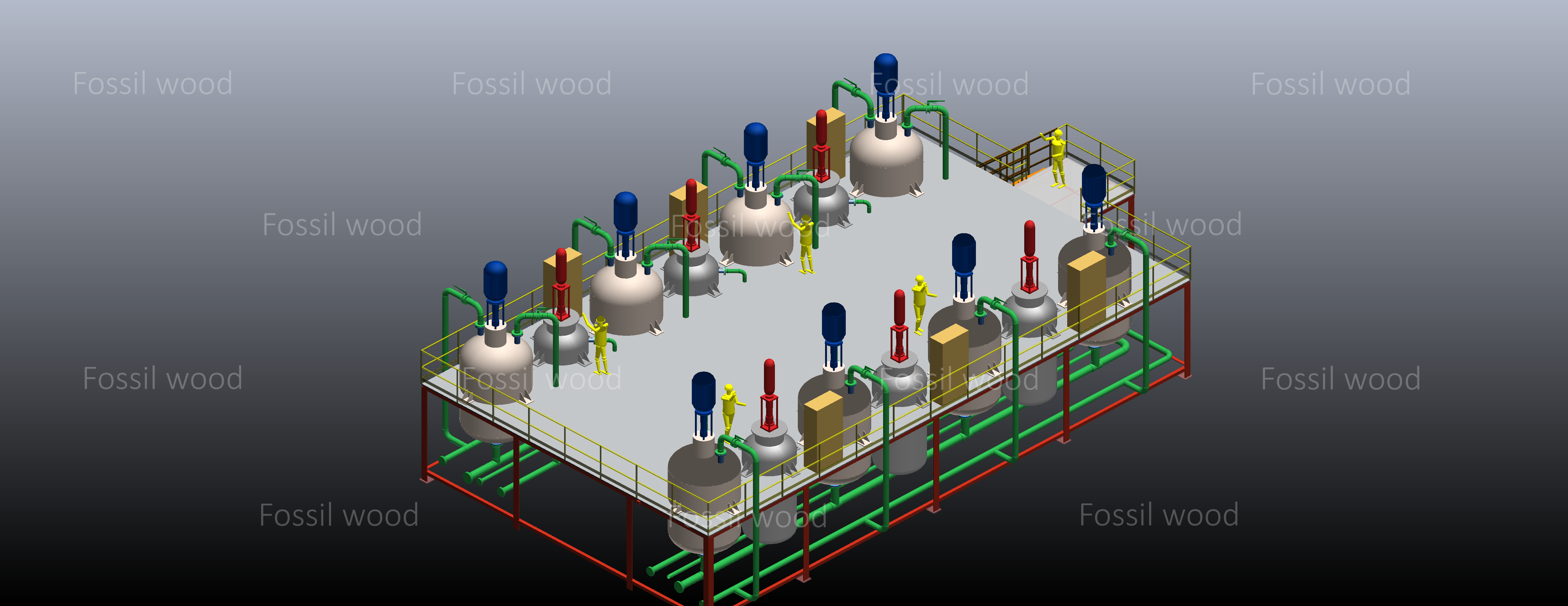

The alcohol-based hand sanitizer production line is mainly composed of pure water RO water treatment, hand sanitizer mixing tank, hand sanitizer storage tank, hand sanitizer filling machine, hand sanitizer labeling machine, and other accessories.

Fossil Wood can provide different production capacity hand sanitizer production lines, which can match different customers' requirements. Our systems are designed for efficiency, quality, and compliance with international standards.

Production Stages

Our comprehensive production line covers all stages from water treatment to final packaging

Mixing & Storage

Hand sanitizer mixing tank and storage tank for efficient production and bulk storage.

Filling & Packaging

Hand sanitizer filling machine and labeling machine for complete packaging solutions.

Production Line Components

Advanced equipment and systems designed for efficient hand sanitizer production

Mixing Tank

Precision blending of alcohol and additives.

Storage Tank

Bulk storage for finished sanitizer product.

Filling Machine

Automated bottle filling with precision dosing.

Labeling Machine

High-speed product labeling and coding.

Quality Control

Comprehensive testing and quality assurance.

Packaging Line

Complete packaging and sealing systems.

Automation

PLC-controlled production management.

Utilities

Essential support systems and infrastructure.

Safety Systems

Fire suppression and safety protocols.

Technical Advantages

Production Flexibility

Our hand sanitizer production lines can be customized to match different customers' requirements. We offer various production capacities to accommodate both small-scale and large-scale operations.

The modular design allows for easy expansion and modification as your business grows, ensuring long-term investment value.

Quality Assurance

All our production lines are Certified, ensuring compliance with international quality standards and safety regulations.

Advanced automation and quality control systems guarantee consistent product quality and reduce human error in the production process.